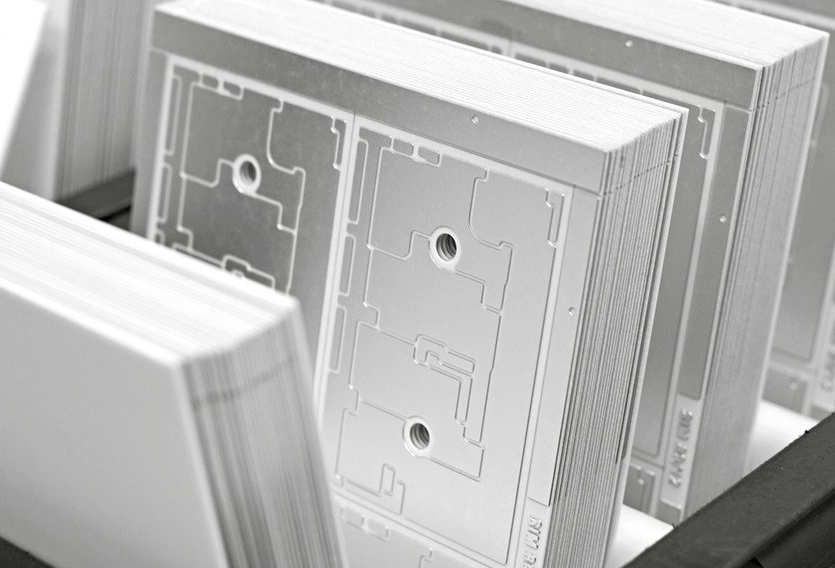

Ceramic substrates AMB technology (Active metal brazing).

Leave your E-mail and we will contact you to clarify the details!

For all questions about the ceramic substrate, please contact by mail ctceramic.amb@gmail.com

1. MATERIAL PROPERTIES

| Items/Types | AlN Aluminum Nitride | Unit |

|---|---|---|

| Density | 3.3 | g/m3 |

| Thermal Conductivity | >170 | W/m * K |

| Coefficient of Thermal Expansion | 4.7 (20℃~300℃) | * 10-6/K |

| Bending Strength (Σ0,M>10) | >350 | MPa |

| Dielectric Loss | 0.0005 | 1MHz |

| Dielectric Constant | 9.0 | 1Mhz |

| Dielectric Strength | >20 | KV/mm |

| Electrical Resistivity | >1014 | Ω *cm |

| E-Modulus | 320 | GPa |

1.02 COPPER PROPERTIES

| Items | Parameters | Unit |

|---|---|---|

| Purity | 99.99 | % |

| O2 Content | OFHC | – |

| Hardness | 60~110 | HV |

| Electrical Conductivity | 58.6 | MS/m |

1.03 AVAILABLE CERAMIC TYPES/THICKNESSES

| CERAMIC THICKNESS | AIN |

|---|---|

| 0.25mm | ✔ 4”* 4” |

| 0.38mm | ✔ 5”* 5” |

| 0.63mm | ✔ 5,5”* 7,5” |

| 1.0mm | ✔ 5,5”* 7,5” |

1.04 COPPER THICKNESSES

| 0.20mm | 0.30mm | 0.50mm | 0.80mm |

1.05 AVAILABLE MATERIAL THICKNESS COMBINATIONS

| CERAMIC THICKNESS | COPPER THICKNESS |

|---|

| 0.20mm | 0.30mm | 0.50mm | 0.80mm | |

|---|---|---|---|---|

| 0.25 mm | AlN | AlN | – | – |

| 0.38 mm | AlN | AlN | AlN | – |

| 0.63 mm | AlN | AlN | AlN | – |

| 1.00 mm | AlN | AlN | AlN | AlN |

For all questions about the ceramic substrate, please contact by mail ctceramic.amb@gmail.com

2. DESIGN FEATURES

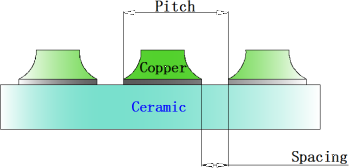

2.01 PATTERN MIN. WIDTH/SPACING DIMENSION

| COPPER THICKNESS | SPACINGS | MIN. PITCH |

|---|---|---|

| 0.20mm | 0.35mm | 0.7mm |

| 0.30mm | 0.55mm | 0.9mm |

| 0.50mm | 0.65mm | 1.1mm |

| 0.80mm | 1.10mm | 2.0mm |

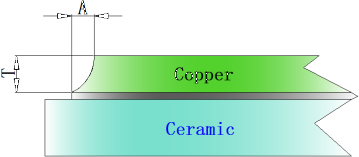

2.02 CERAMIC EDGE PERIMETER

| COPPER THICKNESS | DISTANCE |

|---|---|

| 0.20mm | A≥0.20mm |

| 0.30mm | A≥0.30mm |

| 0.50mm | A≥0.40mm |

| 0.80mm | A≥0.50mm |

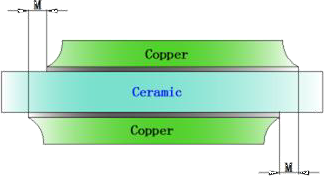

2.03 MISALIGNMENT COPPER PATTERN FRONT/BACK

| DISTANCE |

|---|

| M≤0.2mm |

2.04 ETCHING FACTOR

| ETCHING FACTOR |

|---|

| F=T/A>2 |

About us

WE are a team of professionals with extensive experience in the development, production and supply of high quality products based on ceramics

The company’s specialists have extensive experience in selecting optimal solutions for the production of products, which helps to significantly reduce the costs of their production.

At any time you can get technically competent advice on any issue that interests you.